If you’ve read all the articles I’ve posted so far, by now, you know how much it cost me to produce the High Cookery book. After the production process was completed what I had, in my hands, is a fancy pdf file that I can either take to print and/or convert into an eBook version.

In the old days, the process was extremely straightforward – you produced a book, created inventory, and distributed your copies to the shelves of the bookstores. Today, however, there are alternatives to this model. First, some may choose to only go for the e-version of their book thus eliminating the risk of paying for inventory. Naturally, this means that they will not be able to sell hard copies of their book and may lose some rewards, but, let’s face it – print is a dying medium, and as time progresses the e-alternative will become more and more dominant.

Another common alternative is to go for ‘print-on-demand’ (POD) services. These services print a book once it has been purchased via various online channels and then send it via snail-mail to the purchaser. This option negates the inventory risk as you don’t need to print many copies. However, it prevents you from going to the retailers as they naturally require stock for their shelves. Also, since each book is printed as a one-off, your profit margins per unit tend to be substantially lower (I don’t have hard numbers please challenge this last statement).

If, like me, you wish to create inventory you go for what’s called offset printing. This is the ‘traditional’ process ink is transferred from a plate to a rubber sheet, which then rolls the ink onto paper. When you offset print books, the price per copy is the cheapest and the quality of the book tends to be better. For most books, that level of quality is not an issue as the books are simple – mostly text with, possibly, a few images. However, for image-heavy books where the book-product itself is critical to the reading experience (for example high-end cookbooks…), digital printing cannot meet the same quality standards as offset printing.

When choosing how and where to offset-print there are many variables. If this is your first time, I’d recommend working with a production manager contractor. It will cost you more (in my case it cost an additional $1,750) but in my opinion, it may reduce the overall costs and will definitely increase the chances of a high-quality product.

A production manager utilizes his (I’m using male just because this happens to be the gender of the professional I worked with) network to scout for the best pricing and help navigate you and your designer through the printing facility processes. These include – schedules, pre-press, shipping, import, packaging, payment, and more.

I originally chose to print in China. Printing in China has its pros and cons. It is substantially cheaper which, as you might imagine, is the biggest pro. For the High Cookery book, quotes in the US ranged from 50% to 100% more expensive per copy… Quality standards are similar, though in my experience quality control is much more important when printing in China. The biggest cons are quantities, time to market, and customer service. The operational hassle of printing in China and importing the inventory is not worth it if you’re printing a few hundred copies. To my understanding, the ‘rule of the thumb’ is that the minimum quantity to justify said hassle is 3,000. The sad truth is that most books don’t sell 3,000 copies and therefore many self-publishers are rightfully reluctant to take the inventory risk.

Another important point to consider is time to market – when printing overseas you must take into account a couple of months till delivery. This means that inventory time to market management is critical!

Last, another risk when printing in China is customer service – if problems arise with regards to quality, timing or many other issues – it tends to get more complicated when the person you’re working with is not local and you might not work, talk or behave in the same way. This is where a production manager can really alleviate the pain. However, credit is due where credit is due – when I printed my second book, I received the full 5,000-copy shipment and realized the quality sucks. I was prepared for battle but was pleasantly surprised when the printing facility agreed to take all inventory back and do another, better run at their expense…

Unfortunately, while I was gearing to press the ‘print button’ in China, COVID-19 happened and shut the country down. Luckily, no money was sent and I was free to explore other options. Since I was insistent on releasing the book on the notorious 04/20, I realized I must shift my focus to North America.

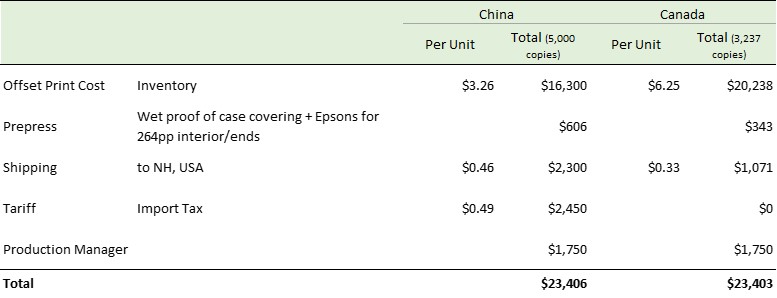

With the help of the production manager, I identified an offset printing facility in Canada and we quickly set everything up. They sent proofs and the process was really painless and much more expensive. Below I provide the inventory cost structure for my first offset print run. It is worth emphasizing that for future prints (in the hopes the book is successful enough…) I believe this cost will be lower as the need for pre-press diminishes.

I was planning to print 5,000 copies in China but ended up printing 3,000 copies due to the price difference (well it ended up as 3,237 copies). As you can see printing 5,000 copies in China and 3,000 in Canada basically cost the same…

With a gross cost of $7.23 per unit and assuming a full retail price of $27.95, one might think the margins are phenomenal. That is unfortunately not the case as there are several other bites in the margin such as promotions, fulfillment, storage, distribution, marketing, and a few other operational costs (not to mention books that get harmed during the shipping and storage and become instantaneously worthless) but I feel I bored you, reader, enough for now… I will talk more in my future posts.